Blog — Vaquform Molds

How to 3D Print Molds for Vacuum Forming

Posted by Joaquin Laurel on

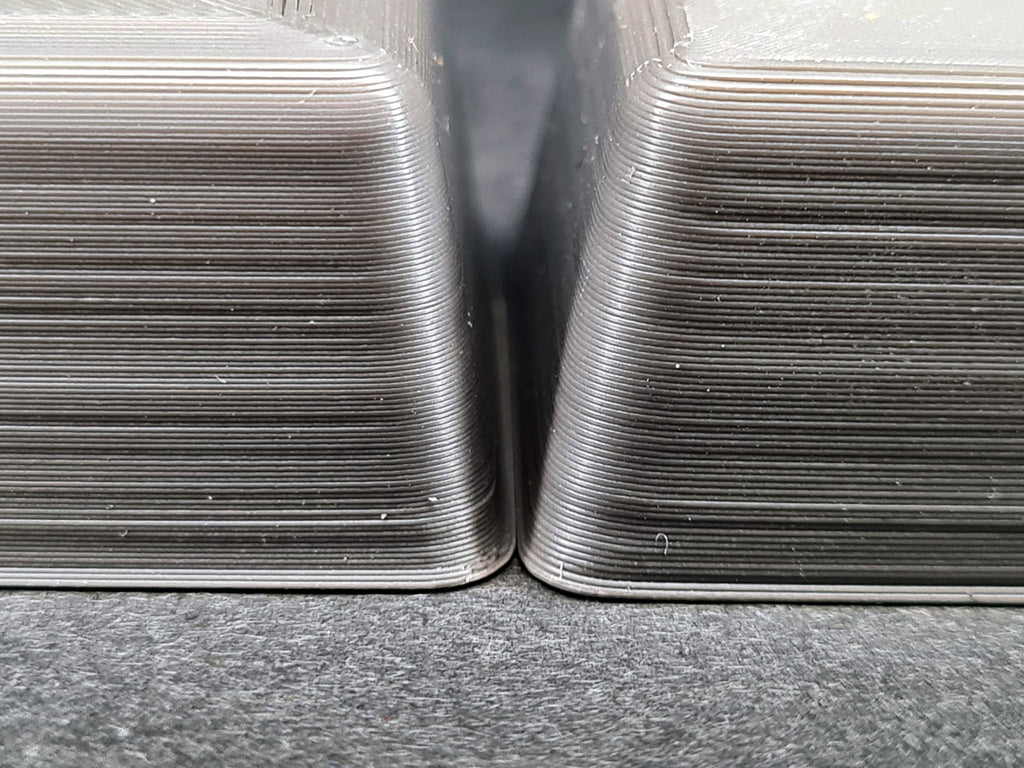

There are many ways to create your Vaquform molds. You may use sculpted clay, Lego pieces, found objects, and many more. As long as the mold can hold its shape under heat, is not wet or dusty, and will not stick to a formed sheet, you can #VaquformIt. But there is one thing that makers out there use a lot and that’s FDM 3D printing. With 3D printing, you can easily and digitally modify your mold designs. This guide will teach you how to optimize your FDM 3D prints for vacuum forming. TL;DR Here's a bullet point summary if you’re here for...

- Tags: 3D Printing, education, Vaquform Molds, Vent Holes

Vent Holes for Vaquform Molds

Posted by Joaquin Laurel on

Well drilled and well placed vent holes could make the difference between a successful or a failed form Surely most of you reading this article are already familiar with the vacuum forming process - a heated plastic sheet is pulled over a mold using a vacuum, which forces the sheet to take the shape of the mold. Creating a strong and effective vacuum is something that Vaquform’s DT2 does exceptionally well. However, a strong vacuum is only part of the equation. In order for the vacuum to be effective, your Vaquform mold must allow air to freely escape from all...

- Tags: Vaquform Molds, Vent Holes