Blog

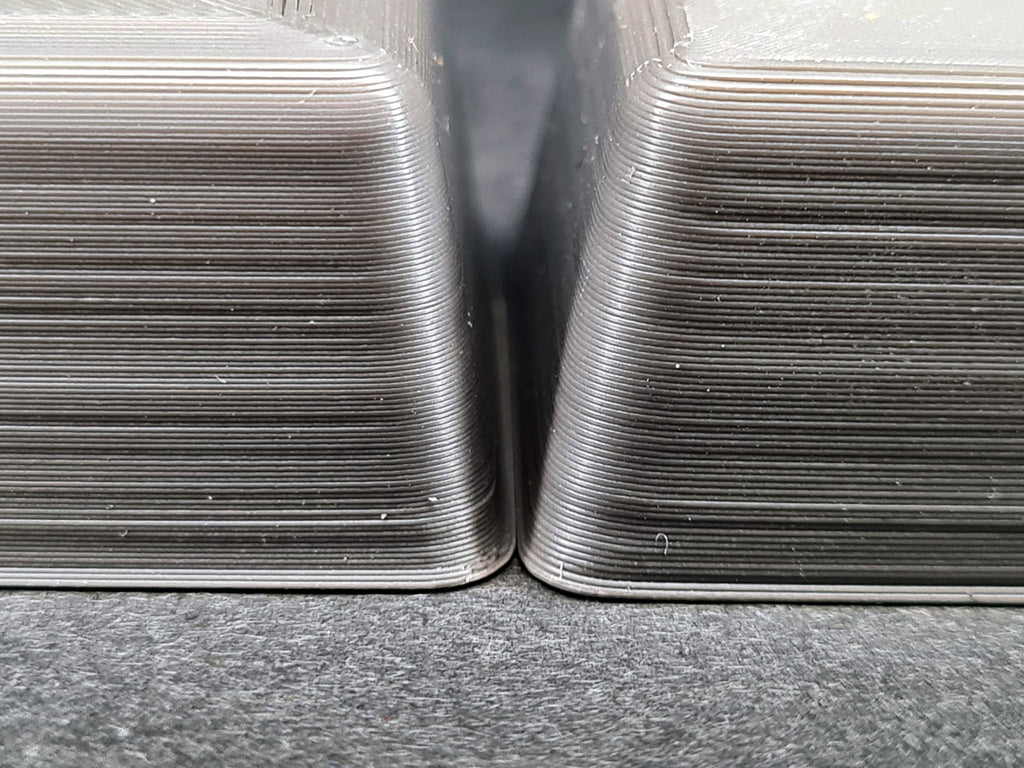

How to 3D Print Molds for Vacuum Forming

Posted by Joaquin Laurel on

There are many ways to create your Vaquform molds. You may use sculpted clay, Lego pieces, found objects, and many more. As long as the mold can hold its shape under heat, is not wet or dusty, and will not stick to a formed sheet, you can #VaquformIt. But there is one thing that makers out there use a lot and that’s FDM 3D printing. With 3D printing, you can easily and digitally modify your mold designs. This guide will teach you how to optimize your FDM 3D prints for vacuum forming. TL;DR Here's a bullet point summary if you’re here for...

- Tags: 3D Printing, education, Vaquform Molds, Vent Holes

Vent Holes for Vaquform Molds

Posted by Joaquin Laurel on

Well drilled and well placed vent holes could make the difference between a successful or a failed form Surely most of you reading this article are already familiar with the vacuum forming process - a heated plastic sheet is pulled over a mold using a vacuum, which forces the sheet to take the shape of the mold. Creating a strong and effective vacuum is something that Vaquform’s DT2 does exceptionally well. However, a strong vacuum is only part of the equation. In order for the vacuum to be effective, your Vaquform mold must allow air to freely escape from all...

- Tags: Vaquform Molds, Vent Holes

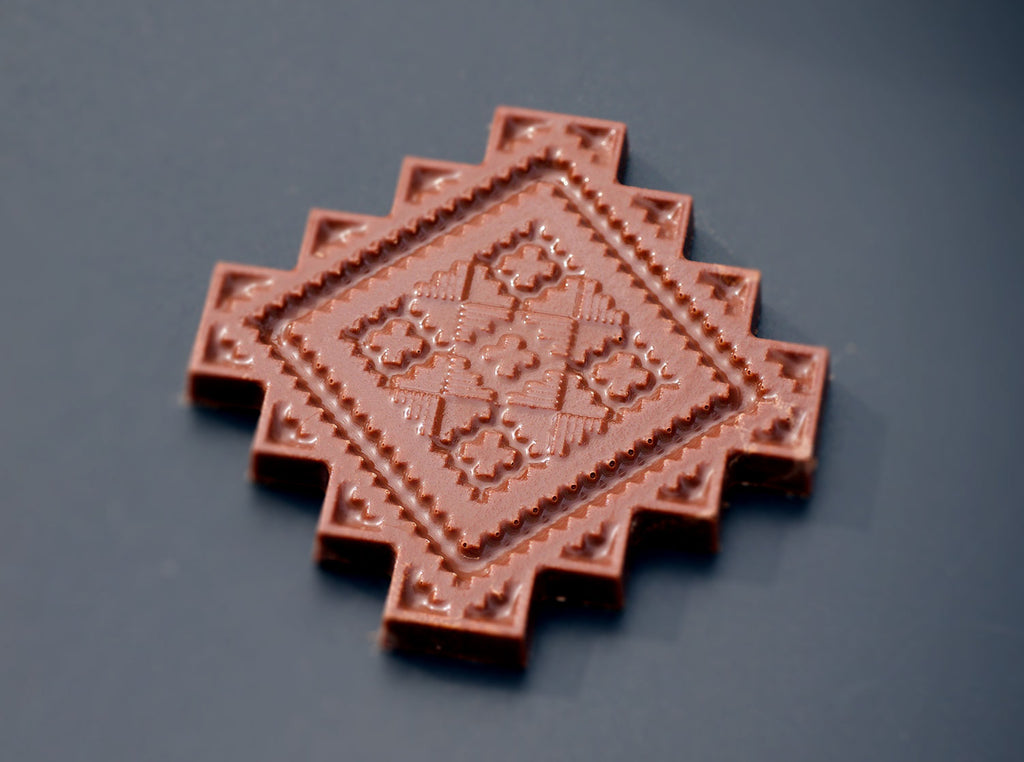

Chocolatier Vaquform Makers Feature

Posted by Alex Abella on

We put Vaquform out into the world knowing full well the possibilities were endless as far as its application was concerned. Right at the very start, we knew this portable machine held so much promise for makers, but it wasn’t until we began seeing the actual works that we started realizing its power to shape not just molds, but entire special interest communities. Such is what Vaquform has been doing for chocolatiers. Using the DT2, gifted artisans from all over the world are leveling up in their craft through custom mold making and even packaging, allowing them to enrich their...

How To Make Custom Chocolate Molds

Posted by Carlo Templo on

Here at Vaquform we like to believe that we have a firm understanding of who we make the machine for. For instance, we know that Vaquform would become a valuable asset to cosplayers who may want to create props or costume pieces that might take forever using more tried and tested methods such as 3D Printing or Foamsmithing. That is just one of the many markets we cater to. What came to us as a surprise however is that Vaquform has become a hot commodity within the chocolate making community to the point that it has become one of our...

How to Make Custom Blister Packaging

Posted by Joaquin Laurel on

Hi, everyone. It’s Joaquin, Vaquform’s newest designer. Now before anything, if you’re looking for tips on DIY packaging, how to create blister packaging, or simply interested in hearing a newbie’s journey from packaging design to mass production with vacuum forming, then you've struck gold my friend!I was hired two months fresh out of design school and since joining the team, I've been fortunate to have already handled a project all on my own already from start to finish. Which is exactly why I’m here! I thought it would be helpful to share with you guys what I learned from my...

- Tags: packaging